Direct procurement is about the purchase of goods and services that a company uses to make its products or provide its services. On the other hand, indirect procurement is for things like IT, HR and facilities that are needed to run a company internally, but do not directly contribute to production.

This distinction isn’t just technical, but it impacts how you budget, manage suppliers, assess risk, and plan for the future. While direct and indirect procurement may appear similar on the surface, treating both the same often leads to inefficiencies and missed opportunities.

In this blog, we’ll break down the difference between direct and indirect procurement and why understanding both is key to building a smarter procurement strategy.

What is direct procurement and why it matters?

Direct procurement means acquiring the goods, materials, or services that are integral to your product or core operations.

It’s the raw ingredients that your business cannot do without, think flour for a bakery, metal sheets for a manufacturer, or servers for a cloud services company.

Here’s why it deserves your close attention:

- Direct impact on revenue and quality

Direct procurement often accounts for over 60–80% of total spend in manufacturing industries, meaning it’s central to your cost structure and product performance. - Strategic supplier collaboration

These suppliers are more than vendors, they’re partners. You negotiate pricing, delivery, quality, and innovation through long-term contracts and close coordination with production teams.

| Pro Tip: Track lead time and defect rate as core procurement KPIs, these reveal supplier reliability and quality issues before they disrupt operations. |

- High stakes, limited margin for error

Even minor disruptions, like a delayed delivery or quality slip, can halt production lines and erode margins. - Opportunity for big savings

Because direct spend makes up so much of total procurement budgets, even a 1–2% optimization translates into substantial dollar savings. - Essential for ESG and compliance goals

Sustainability is no longer optional. Procurement strategy increasingly weaves in ESG criteria, from carbon footprint to responsible sourcing, to guide direct supplier selection and operations.

| Expert note: According to supply chain leader Remko van Hoek, strategic sourcing is all about supplier relationships, innovation, and long-term performance, elements that matter most in direct procurement |

What is indirect procurement?

Indirect procurement is the process of sourcing goods and services that support business operations but don’t directly contribute to the final product or service. These purchases keep your internal teams productive and your infrastructure running reliably.

You’re looking at things like:

- Office supplies and IT equipment

- Facility maintenance and utilities

- Cybersecurity services and SaaS subscriptions

- HR tools, payroll systems, and employee training

- Professional services like legal, consulting, and marketing

While these costs don’t appear in your bill of materials, their impact is very real. Indirect procurement system influences:

- Operational continuity

- Employee experience and productivity

- Internal compliance and cost control

- Overall business agility

In service-heavy sectors like healthcare, banking, and SaaS, where the “product” is mostly intangible, indirect procurement is often known as the primary driver of operational efficiency. It largely determines how effectively teams can deliver value to customers.

Managing indirect procurement can be tricky.

It’s usually decentralized, spread across departments, and filled with smaller, recurring purchases. Whereas direct procurement follows structured planning cycles, indirect procurement is often reactive, making visibility and control harder to maintain.

| Stat: According to Gartner, organizations that centralize indirect procurement reduce total indirect spend by up to 15%, simply by eliminating maverick buying and consolidating suppliers. |

In short, indirect procurement may work behind the scenes; but it plays a front-line role in ensuring your teams are equipped, connected, and compliant.

Learn about procurement vs purchasing.

Organizations that strategically manage indirect procurement achieve cost savings 20-30% higher than those focusing solely on direct procurement.

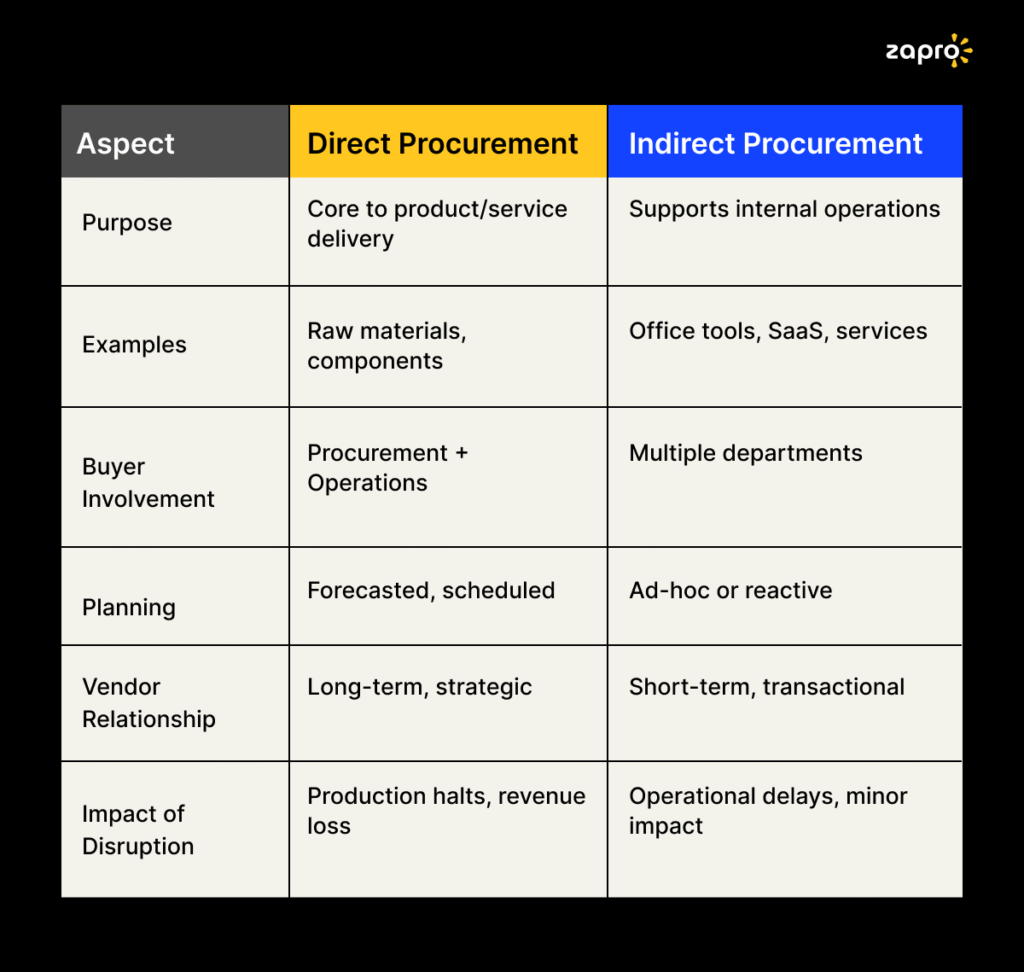

Key differences between direct and indirect procurement

Direct procurement refers to the purchasing of raw materials, components, and goods that are directly incorporated into the final product a company sells, while indirect procurement involves purchasing goods and services that are required to run the business day-to-day but do not end up in the final product.

Here are the key areas where they differ:

1. Purpose and impact

Direct procurement involves inputs directly tied to your product or service. Without it, the business can’t deliver value to customers. Whereas indirect procurement supports internal functions, enabling the business to operate smoothly rather than produce.

2. Vendor relationships

Direct procurement relies on stable, long-term supplier partnerships. Vendor performance directly impacts product quality. Indirect procurement, on the other hand, is known for more transactional relationships, often involving interchangeable vendors.

3. Planning and forecasting

Direct spend is closely linked to production schedules and customer demand. Whereas indirect spend is often ad-hoc, driven by internal requests and evolving needs.

4. Budgeting and control

Direct procurement typically follows structured, centrally reviewed budgets. Indirect procurement, while essential, is usually decentralized, making control more challenging without the right tools.

5. Inventory management

Inventory control is central to direct procurement; companies maintain stock levels, buffer inventory, and safety margins. Indirect goods are rarely stocked in the same way; they’re typically purchased as needed, without long-term inventory planning.

6. Risk exposure

Supply disruptions in direct procurement software can halt production and affect customer delivery. Indirect procurement carries operational risks, like delays in onboarding or outages, but rarely impacts revenue directly.

7. Digitalization and automation

Indirect procurement is often the first to be automated through procurement tools due to its volume and repetitive nature. Direct procurement, on the other hand, requires more customization and integration with production systems.

8. Stakeholder involvement

Direct procurement involves procurement, operations, and quality teams. Indirect procurement is driven by departments like HR, IT, and admin, each with different priorities.

Learn about best procurement software.

To Summarize:

| Aspect | Direct Procurement | Indirect Procurement |

| Core Purpose | Acquires materials/services tied directly to the company’s offering | Supports internal operations and functional needs |

| Examples | Raw materials, components, packaging, manufacturing services | Office supplies, software tools, travel, facility services |

| Frequency of Purchase | Recurring and volume-driven | Irregular or one-off purchases |

| Typical Buyers | Procurement + operations + production teams | Departmental heads (IT, HR, admin, marketing) |

| Budget Ownership | Centralized, tied to cost of goods sold (COGS) | Decentralized, part of departmental budgets |

| Impact of Disruption | Can halt production and affect customer delivery | May disrupt internal efficiency but rarely impacts customers directly |

| Key KPIs | Cost of goods sold, supplier lead time, quality compliance, inventory turnover | Cost savings, process efficiency, request-to-approve cycle time |

| Supplier Relationship | Long-term, strategic partnerships | Often transactional and price-sensitive |

| Compliance Requirements | Strict regulatory, technical, and quality standards | Focus on policy compliance, spend thresholds, preferred vendor usage |

| Supplier Lifecycle | Longer onboarding, extensive vetting, contract negotiation | Faster onboarding, simplified approvals |

| Digitalization Priority | Tailored systems integrated with production (e.g., ERP + MES) | More suited for automation through e-procurement platforms |

| Inventory Strategy | Safety stock, just-in-time (JIT), demand forecasting | Minimal inventory, usually procured on demand |

Zapro – One platform for everything procurement

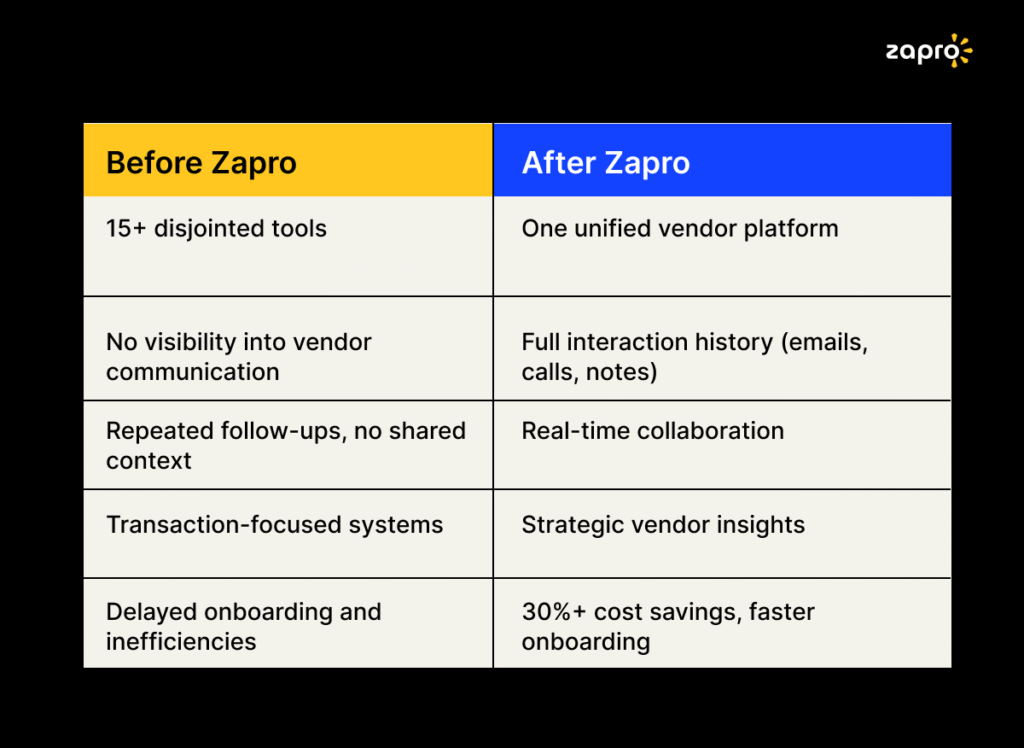

Understanding the difference between direct and indirect procurement isn’t just a technical detail, it’s essential to building a resilient and cost-efficient business.

While most teams rely on multiple disconnected tools, Zapro brings sourcing, contracts, vendors, compliance, and collaboration into a single unified workspace.

Instead of juggling spreadsheets, inboxes, CLM tools, document drives, and third-party risk platforms, Zapro centralizes everything and is often called as a CRM built specifically for suppliers.

That’s exactly where Zapro comes in.

Instead of juggling 15+ disconnected tools, like spreadsheets, sourcing platforms, contract systems, email chains, and document drives, Zapro brings everything into a single, unified workspace.

It replaces:

- Spreadsheets for vendor tracking

- Shared inboxes for communication

- CLM tools for contracts

- eSourcing platforms for RFQs

- Google Drive or SharePoint for documents

- Separate risk and compliance tools

- Even third-party risk management software like Vanta, by centralizing all your vendor interactions, documents, and audit trails in one place

Think of Zapro as a CRM for your suppliers, purpose-built for procurement teams. It helps you:

- Cut onboarding time in half

- Track every touchpoint—emails, calls, contracts, issues

- Flag risky or unreliable vendors early

- Enable smoother collaboration across procurement, finance, legal, and ops

In short, Zapro turns procurement into a strategic advantage. It gives you full control over both direct and indirect spend, while quietly eliminating complexity behind the scenes.

If you’re ready to move beyond fragmented processes and unlock the full potential of procurement, Zapro is your next step forward.

Master Both Direct and Indirect Procurement — Start Saving Smarter Today!

FAQs

What is the difference between direct and indirect procurement?

Direct procurement, known as the process that covers what you need to create your core product or service, focuses on production-critical inputs. On the other hand, there’s indirect procurement, often called the backbone of internal operations, that takes care of everything that supports how your business functions day to day.

How do direct and indirect procurement impact business profitability?

Direct procurement impacts product margins and cost of goods sold most directly. Indirect procurement affects profitability through measures such as operational effectiveness, cost limitation and staff productivity. It is worth noting that one has a direct impact on revenue while the other influences the efficiency of the business operations.

What should you look for in direct and indirect procurement software?

A current procurement platform should have the capability to handle both. Features like supplier management, spend visibility, workflow automation, compliance tracking, and audit trails are a part of this. While for direct procurement, deeper system integrations are necessary, indirect procurement requires automation and centralized control; hence, a comprehensive platform like Zapro is perfect.

Don’t miss our weekly updates

We’ll email you 1-3 times per week—and never share your information.

Healthcare

Healthcare Financial Services

Financial Services Technology

Technology Venture Capitalist

Venture Capitalist Chief Procurement Officer

Chief Procurement Officer Chief Financial Officer

Chief Financial Officer