Introduction

Many businesses today have a good understanding of vendor and supplier relationship management, as it forms the backbone of their operations. A good relationship with a vendor leads to growth, profitability, and a positive reputation, according to a study conducted by Deloitte. Even though many companies are well aware of these facts, a few woefully miss monitoring how their vendors are actually performing. This cannot be ignored because a missed delivery, poor-quality product, or weak service level can quickly disrupt operations and derail customer trust.

With vendor performance management, it is easy to monitor, measure, and improve how vendors deliver against agreed expectations. The structured process in VPM equips businesses to track and improve to meet the expectations. By tracking supplier performance with clear metrics and feedback loops, businesses can minimize risks, protect costs, and continuously build partnerships that drive value creation.

In this post, we explore:

- What vendor performance management really means.

- Why it’s critical for modern businesses.

- The step-by-step vendor performance management process.

- The most important supplier performance metrics and KPIs.

- Best practices and future trends shaping this space.

- How platforms like Zapro can help streamline and automate the entire process.

Let’s get started by understanding the foundation

What is Vendor Performance Management?

The term vendor performance management (VPM) denotes following up and assessing the performance of products or services provided by vendors compared to what was promised in the contract. The evaluation throws insights into compliance, accountability, and creating a framework for continuous improvement.

A few in the business world understand the subtle difference between the terms vendor performance management and supplier performance management. Depending on the transaction and other factors, the terms are interchangeable.

Vendor Performance Management vs. Supplier Performance Management

| Aspect | Vendor Performance Management (VPM) | Supplier Performance Management (SPM) |

| Scope | Focuses on vendors who sell goods or services directly to your organization. | Broader in scope, often includes raw material suppliers and third-party service providers across the supply chain. |

| Objectives | – Ensure vendors meet or exceed expectations.- Track KPIs for vendor management such as quality, cost, and delivery.- Identify risks early and mitigate them.- Build long-term, mutually beneficial relationships. | Similar objectives but applied across a wider supply chain ecosystem, ensuring raw materials, logistics, and third-party services align with organizational goals. |

| Impact | Moves beyond compliance to become a strategic capability that improves efficiency, reduces costs, and strengthens vendor partnerships. | Enhances overall supply chain visibility, risk management, and operational resilience across multiple tiers of suppliers. |

The Business Case for Vendor Performance Management

Is vendor performance management crucial for business success?

Why should a lot of interest, time, resources, and attention go to VPM?

Yes, vendor performance management is crucial for business success. The results are rewarding, easy to measure, and gauge for future success. Here is how it is useful:

Cost reduction

Through continuous tracking of supplier performance metrics, businesses can identify inefficiencies, eliminate poor-performing vendors, and negotiate better terms without any delay and with fewer resources. According to a McKinsey research study, companies demonstrated 12% lower procurement costs with strong VPM.

Risk mitigation

By putting a structured vendor performance management process in place, companies can gain clear visibility about compliance issues and late deliveries. It is essential to understand the fact that every vendor carries risk, whether financial, operational, or reputational and might lead to bigger problems, if they are overlooked.

Quality improvement

Compelling vendor performance management guarantees best in class product and service quality at all times. Monitoring vendor performance through quality KPIs helps businesses uphold standards and reduce customer complaints.

Relationship optimization

Performance reviews are not just about penalizing vendors. They open the door to collaboration, allowing both sides to discuss challenges and opportunities. This facilitates more robust partnerships and shared innovation.

In short: businesses that invest in VPM enjoy better quality, lower costs, reduced risks, and stronger vendor relationships all of which improve competitiveness in the market.

76% of public sector vendor management offices (VMOs) use a balanced scorecard methodology to measure vendor performance against business outcomes.

Key Components of Effective VPM

An effective vendor performance management process has several building blocks:

Performance metrics and KPIs

Defining the right supplier performance metrics is essential. These can include quality, delivery times, service levels, and cost efficiency.

Monitoring and assessment frameworks

Regular monitoring ensures vendors are on track. Assessment frameworks include dashboards, automated tools, and periodic reviews.

Feedback and communication systems

Open communication ensures vendors know where they stand. Feedback sessions foster trust and help vendors take corrective action.

Improvement planning

Beyond tracking, VPM should encourage vendors to continuously improve through joint problem-solving, training, or innovation initiatives.

When all four elements work together, businesses create a balanced system that rewards good performance and addresses issues before they escalate.

Learn more about vendor management tools.

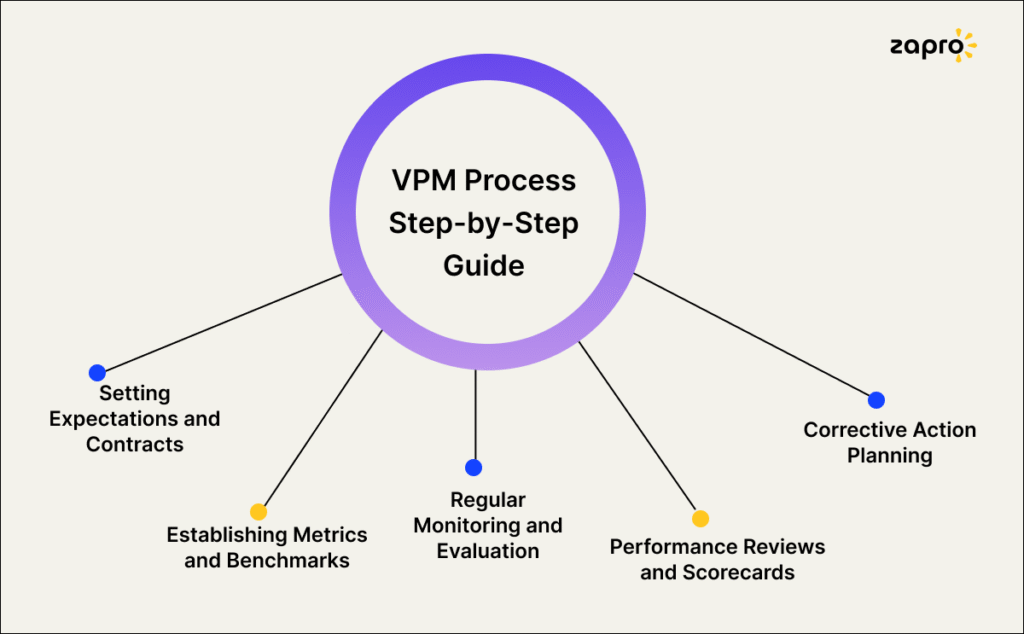

VPM Process: Step-by-Step Guide

Let’s walk through the vendor performance management process step by step.

Step 1: Setting expectations and contracts

Begin by clearly defining deliverables, timelines, quality standards, and penalties in vendor contracts management. This sets the foundation for evaluation.

Step 2: Establishing metrics and benchmarks

Identify supplier performance metrics such as defect rates, delivery times, and cost savings. Benchmarks should align with business goals.

Step 3: Regular monitoring and evaluation

Track vendor activities on a regular basis. This could be monthly performance dashboards or quarterly scorecards.

Step 4: Performance reviews and scorecards

Conduct structured reviews with vendors, using scorecards to assess results. Compare performance against KPIs and benchmarks.

Step 5: Corrective action planning

If issues are found, develop corrective action plans. Collaborate with vendors to resolve problems and prevent future lapses.

Supplier performance management examples:

- A logistics vendor is evaluated on delivery timeliness and accuracy of shipments.

- An IT service vendor is measured on system uptime and resolution time for incidents.

This structured approach ensures consistency, accountability, and continuous improvement.

Essential Metrics for Vendor Performance

To measure vendor performance effectively, organizations must focus on the right metrics. Common supplier performance metrics include:

- Quality metrics

- Defect rates, error frequency, compliance with specifications.

- Defect rates, error frequency, compliance with specifications.

- Delivery performance

- On-time delivery percentage, lead time adherence.

- On-time delivery percentage, lead time adherence.

- Cost management

- Price competitiveness, cost-saving contributions, total cost of ownership.

- Price competitiveness, cost-saving contributions, total cost of ownership.

- Service level adherence

- Meeting SLAs for support, response times, or uptime guarantees.

- Meeting SLAs for support, response times, or uptime guarantees.

- Innovation contribution

- Suggestions for process improvements, new technologies, or value-added services.

- Suggestions for process improvements, new technologies, or value-added services.

These KPIs create a balanced scorecard that reflects not just cost but the overall value delivered by vendors.

Technology Solutions for VPM

Managing vendor performance manually with spreadsheets is time-consuming and error-prone. Modern businesses rely on technology to automate the vendor performance management process.

Manual vs. Automated Approaches

- Manual: Prone to errors, difficult to scale, limited visibility.

- Automated: Real-time dashboards, standardized processes, and data-driven insights.

Key features in VPM platforms

- Vendor scorecards and dashboards.

- Automated KPI tracking and alerts.

- Integration with procurement, ERP, and finance systems.

- Compliance tracking and audit trails.

Integration capabilities

The best platforms integrate seamlessly with existing procurement and financial systems, creating a unified view of supplier performance.

Reporting and Analytics

Advanced analytics help companies spot trends, predict risks, and identify opportunities for cost savings or quality improvements.

Popular solutions include APM vendors (application performance management vendors), but in procurement, performance management vendors like Zapro are increasingly offering dedicated tools.

Master Vendor Performance Effortlessly

Five Best Practices for Tracking Vendor Performance Management

Here are five proven practices to improve vendor performance management:

Set clear, measurable KPIs

Define KPIs upfront so both you and the vendor know what success looks like. These could cover quality, delivery timelines, cost savings, or innovation. When vendors understand what’s being measured, they are more likely to stay aligned with your goals.

Implement automated monitoring

Manual tracking can be time-consuming and prone to errors. By using software tools and dashboards, you can automatically capture performance data in real time. This not only saves effort but also gives you more accurate insights into vendor performance.

Use standardized scorecards

A standardized scorecard creates a fair system for comparing different vendors. It allows you to evaluate suppliers against the same set of metrics like cost, quality, and service. This consistency ensures transparency and supports better decision-making.

Foster collaborative reviews

Vendor reviews should not feel like audits; they should be two-way conversations. Involving vendors in the discussion helps identify challenges and opportunities for improvement. This collaborative approach builds trust and strengthens long-term partnerships.

Apply data-driven insights

Relying on gut feeling often leads to biased decisions. Instead, use analytics and performance reports to guide actions, identify patterns, and predict risks. Data-backed decisions make vendor performance management more strategic and reliable.

These best practices help organizations build a fair and transparent system that improves both performance and relationships.

Future of Vendor Performance Management

The future of VPM is shaped by technology and data. Emerging trends include:

- Automation and AI: Automating monitoring and using AI for predictive analytics.

- Predictive risk management: Identifying risks before they occur through advanced modeling.

- Integrated ecosystems: Seamless integration of VPM platforms with ERP, CRM, and procurement tools.

- Sustainability metrics: Adding ESG (environmental, social, governance) factors into supplier performance.

APM vendors and other performance management vendors are investing heavily in predictive and AI-driven tools, giving companies more control and foresight than ever.

How Zapro Helps with Vendor Performance Management

Zapro offers a powerful solution for businesses looking to modernize their vendor performance management process. Its features include:

- Automated KPI tracking: Real-time dashboards and alerts.

- Integrated vendor scorecards: Standardized evaluations across all vendors.

- Collaboration tools: Shared workspaces for vendor communication and review.

- Data analytics: Insights into supplier performance trends, risks, and opportunities.

- Compliance and governance: Built-in tools for audit trails and regulatory reporting.

By adopting Zapro, companies can cut costs, improve vendor accountability, and create stronger, more resilient supplier partnerships.

Conclusion and Next Steps

Vendor performance management is no longer optional—it’s a business necessity. By implementing structured processes, using the right KPIs, and adopting technology-driven tools, companies can unlock cost savings, reduce risks, and strengthen vendor relationships.

The takeaway is clear: businesses that treat vendor management strategically gain a competitive edge. And with platforms like Zapro, the process becomes seamless, transparent, and future-ready.

Elevate Vendor Performance with Zapro

Simplify tracking, boost accountability, and drive better results—all in one powerful platform.

FAQ

Q1. What are vendor management KPIs?

Vendor management KPIs are the key numbers or measures you use to track how well a vendor is doing. They cover things like quality, delivery speed, cost efficiency, and compliance with agreements. These KPIs make it easier to see if supplier performance is on track with your business needs.

Q2. Why are vendor management KPIs important?

Without clear KPIs, it’s hard to know if a vendor is actually adding value or holding you back. KPIs give structure to the vendor performance management process by setting clear expectations and accountability. They also allow apm vendors and performance management vendors to provide more reliable insights for improvement.

Q3. What are examples of vendor performance KPIs?

Some useful supplier performance metrics include defect rates, on-time delivery, cost savings, service-level adherence, and even how much a vendor contributes to innovation. These indicators show whether vendor performance is improving or slipping. Tracking them creates supplier performance management examples that teams can learn from and build on.

Q4. What is the difference between vendor management and supplier performance management?

Vendor performance management is about the bigger picture — the overall relationship and whether it delivers long-term value. Supplier performance management focuses more on the numbers, like delivery accuracy, costs, and compliance. In many cases, performance management vendors combine both so businesses get the best of strategy and measurable results.

Q5. How often should vendor performance reviews be conducted?

Most businesses hold reviews every quarter as part of their vendor performance management process. For key vendors, especially in critical supply chains, reviews may happen monthly along with real-time monitoring. This consistent rhythm helps organizations keep an eye on supplier performance metrics and quickly address issues.

Don’t miss our weekly updates

We’ll email you 1-3 times per week—and never share your information.

Healthcare

Healthcare Financial Services

Financial Services Technology

Technology Venture Capitalist

Venture Capitalist Chief Procurement Officer

Chief Procurement Officer Chief Financial Officer

Chief Financial Officer