AI Procurement Software Solution: Next-Gen Source-to-Pay Efficiency

Streamline procurement with smarter supplier, spend, and data management.

TRUSTED BY LEADING BRANDS

Archaic platforms are crippling your

procurement workflows

Understand the hurdles in manual procurement processes

Rigid procurement processes cause inefficiencies and delays, consuming too much time and escalating costs, ultimately obstructing growth.

- Impede your team’s ability to respond swiftly to market demands.

- Communication barriers affect precision & misalign supplier expectations.

- Negative impact on the overall profitability and efficiency of procurement.

Experience the unmatched

procurement efficiency

Automate Processes

Save Costs

Manage Suppliers

Track Performance

Empower Users

Streamlined procurement process

- Streamlined processes lead to faster turnarounds and better relations.

- Digitization reduces errors, allowing you to focus on strategic initiatives.

- Real-time updates ensure transparency and quicker informed decisions.

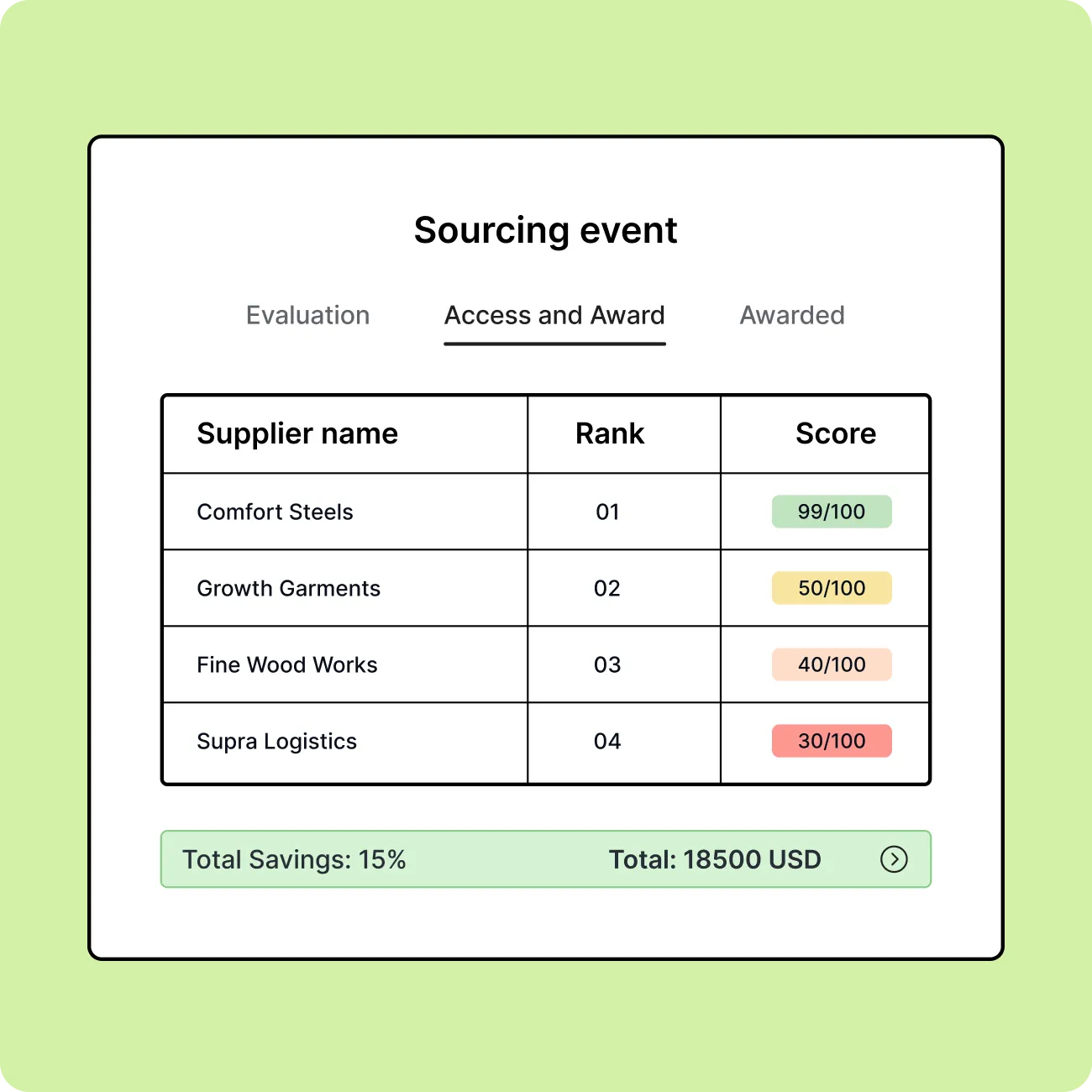

Increased cost savings

- Eliminate maverick spend through precise spend analysis.

- Achieve savings with favorable contract negotiations.

- Ensure quality and value using pre-approved supplier lists.

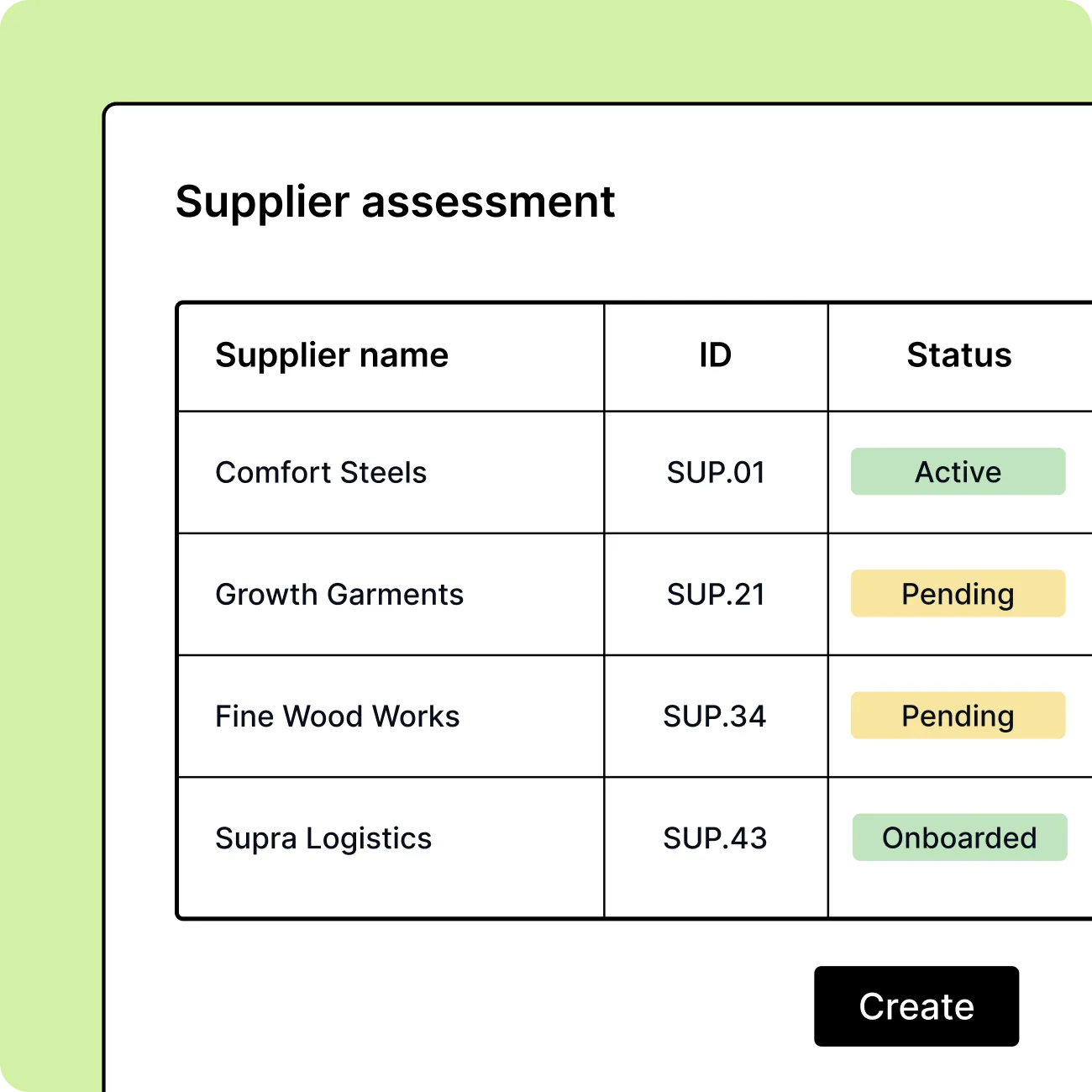

Improved supplier management

- Centralized system for seamless supplier collaboration.

- Enhances communication and reduces supply chain disruptions.

- Automates assessments, saving time and improving efficiency.

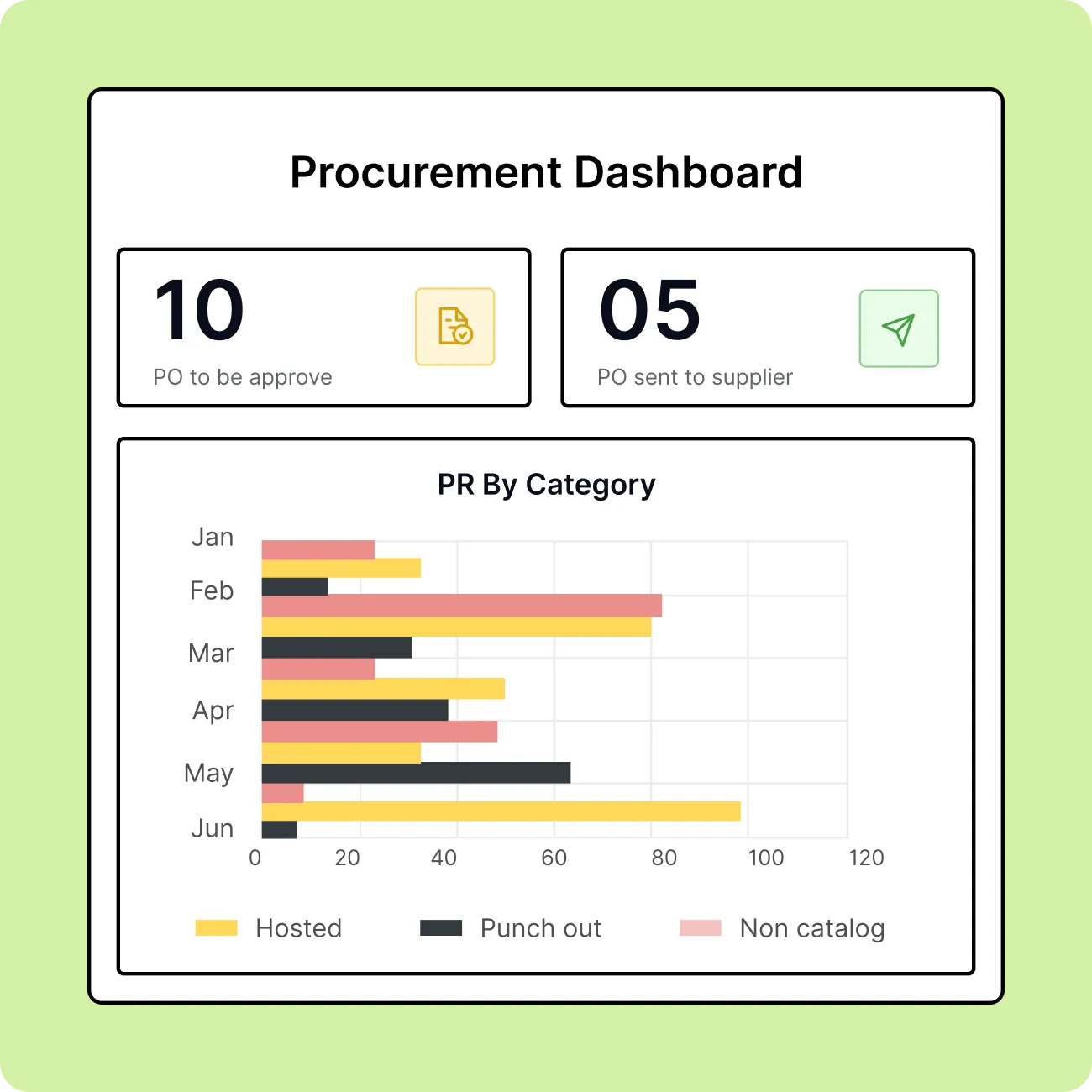

Embrace proactive procurement

- Monitor supplier KPIs and track activities in real-time.

- A data-driven approach to help anticipate market fluctuations.

- Customize reports to assess and address performance trends.

User-friendly and secure

- Empower teams with Zapro’s intuitive interface.

- Boost user adoption for strategic goal alignment.

- Uncover insights instantly with Zapro’s inbuilt AI.

Standout Features of Zapro

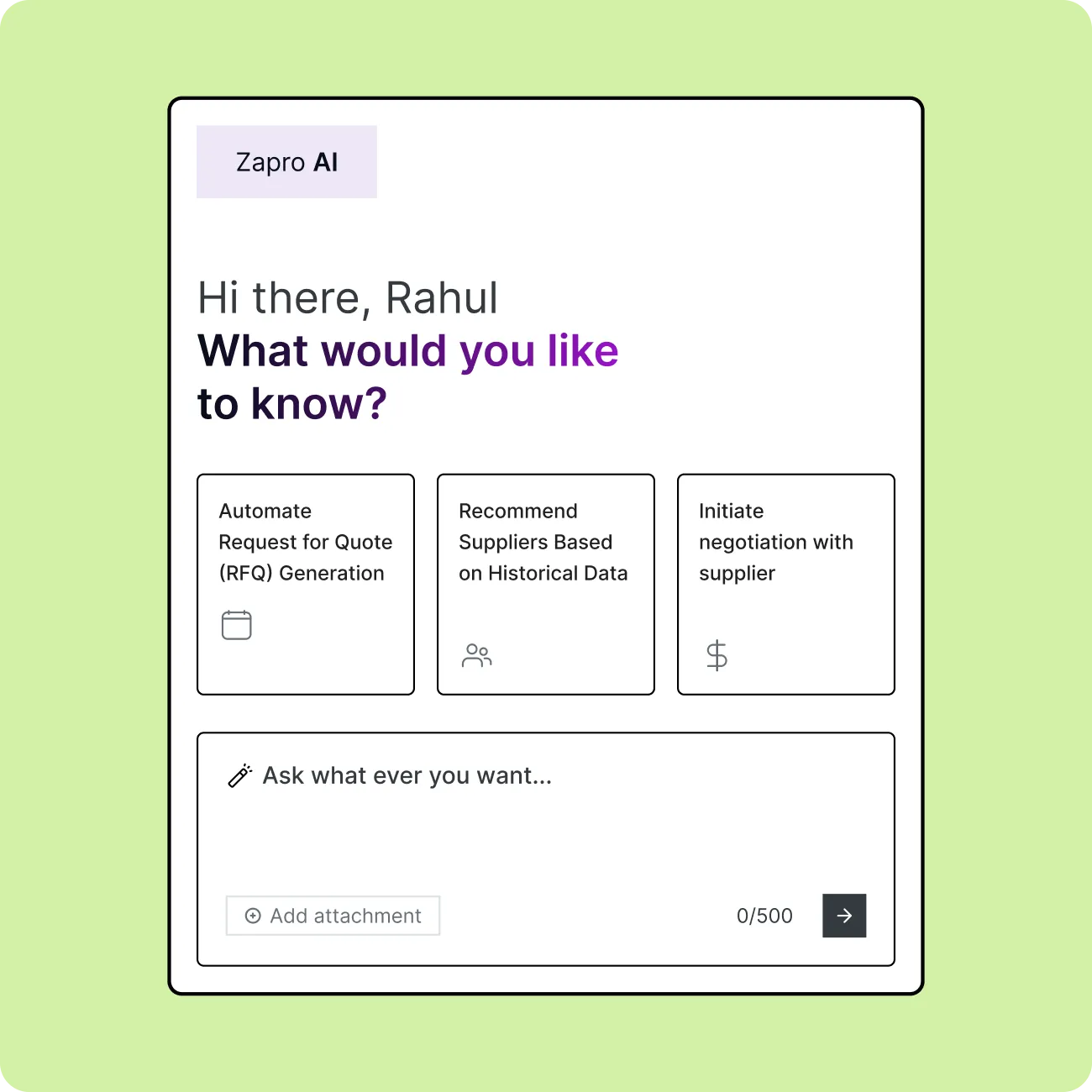

AI Procurement Platform

Dynamic Approvals

Go above visual workflow builders with the ease of adding conditional items and tailoring custom actions for each.

Smart Anomaly Detection

Instantly resolve disruptions with an ultimate approver that swiftly identifies workflow problems.

Punch-Out Catalog

Link with leading retailers such as Amazon, Walmart, eBay, and Target to keep your product information up-to-date.

A holistic procurement solution

tailored to your industry

We empower technology firms by streamlining complex procurement processes, enabling seamless integration and enhanced productivity.

In the hospitality sector, we simplify the procurement processes, improving service delivery while adhering to complex regulations.

Our platform enhances compliance and cost-efficiency in financial services, translating into a more robust and transparent procurement practice.

The Future of Procurement Is Here.

Automate your entire procurement cycle from sourcing to reconciliation with collaborative, agentic, AI-powered procurement software.

The Voice of Our Customers

“Implementing Zapro improved our vendor coordination significantly, leading to a substantial reduction in costs and faster vendor onboarding.”

— Akhil Sikri CTO, zolo

Read Case Study

“Zapro’s strategic sourcing tools have allowed us to negotiate superior contracts and realize significant cost savings.”

— Frank Esmeijer Vice President Development, Bob W

Read Case Study

“Zapro made procurement effortless with a user-friendly interface and stellar support. Our team and suppliers adapted quickly, and we’re now seeing faster approvals and smoother collaboration.”

— Maria Rowan Business Controller, Repromed

Read Case StudyFAQs

What is a procurement solution?

A procurement solution is a software platform designed to streamline and automate the purchasing process within an organization. It helps businesses efficiently manage supplier interactions, purchase requisitions, order processing, and spend management to improve overall procurement efficiency and cost-effectiveness.

How does your eProcurement software work?

Our procurement solution is designed to streamline and automate the entire procurement process, from requisition to payment. It encompasses various functionalities, such as supplier management, order processing, contract management, and spend analysis, thereby enhancing the efficiency, control, and strategic value of procurement activities. By offering a centralized platform, Zapro simplifies approval workflows, minimizes manual errors, and fosters better supplier relationships, ultimately leading to cost savings and improved compliance in procurement operations.

What are the benefits of using your procurement system?

Using our procurement system offers numerous benefits, including enhanced efficiency in purchasing processes, improved supplier relationship management, cost savings, robust security features, and the ability to generate insightful analytics to support tactical and strategic decisions.

Why choose your procurement software over other e-procurement software vendors?

Choosing Zapro gives you access to a user-friendly mobile app with an intuitive interface and multi-language support. Our systems are designed for optimal collaboration across teams and come with robust security features to ensure your procurement processes are safe and efficient.

What industries can benefit from using eProcurement software?

Industries such as hospitality, financial services, and technology can significantly benefit from using eProcurement software. These sectors often deal with complex procurement needs where streamlining processes can lead to substantial cost and time savings.

Can your procurement software handle indirect procurement?

Yes, our procurement software is equipped to manage indirect procurement effectively. It offers tools and features specifically designed to deal with challenges related to non-core purchases, ensuring smooth operations and accurate spend management.

How does procurement software support compliance management?

Procurement software supports compliance management by incorporating regulatory requirements into the procurement workflows. It enforces compliance checks, automates audit trails, and provides reporting features to ensure adherence to industry standards and regulations.

What is indirect procurement software?

Indirect procurement software is used for the purchasing of goods, services, and resources that support a business’s daily operations. The software is useful in enhancing overall purchasing efficiency, thereby helping big in streamlining supplier management, and controlling costs.

What can I expect in a procurement software demo?

A procurement software demo helps understand the features of the software. Learn how automating the procurement process enables you to spend tracking, manage suppliers, and generate reports.

How does an AI procurement software solution save costs?

With AI procurement software solutions you can identify demand, cost-effective suppliers, spend patterns, reduce overpayments and waste in procurement.

Is it possible to get a demo of Zapro’s procurement solution?

Absolutely! You can request a demo of our procurement solution to explore its features and see first-hand how it can benefit your organization’s procurement processes. Simply reach out to our sales team through our website to schedule your personalized demo today.

Healthcare

Healthcare Financial Services

Financial Services Technology

Technology Venture Capitalist

Venture Capitalist Chief Procurement Officer

Chief Procurement Officer Chief Financial Officer

Chief Financial Officer